How to Test Paint Protection Film (PPF) Quality in Dubai | Complete Guide

How to Test the Quality of Paint Protection Film (PPF) in Dubai: A Complete Guide

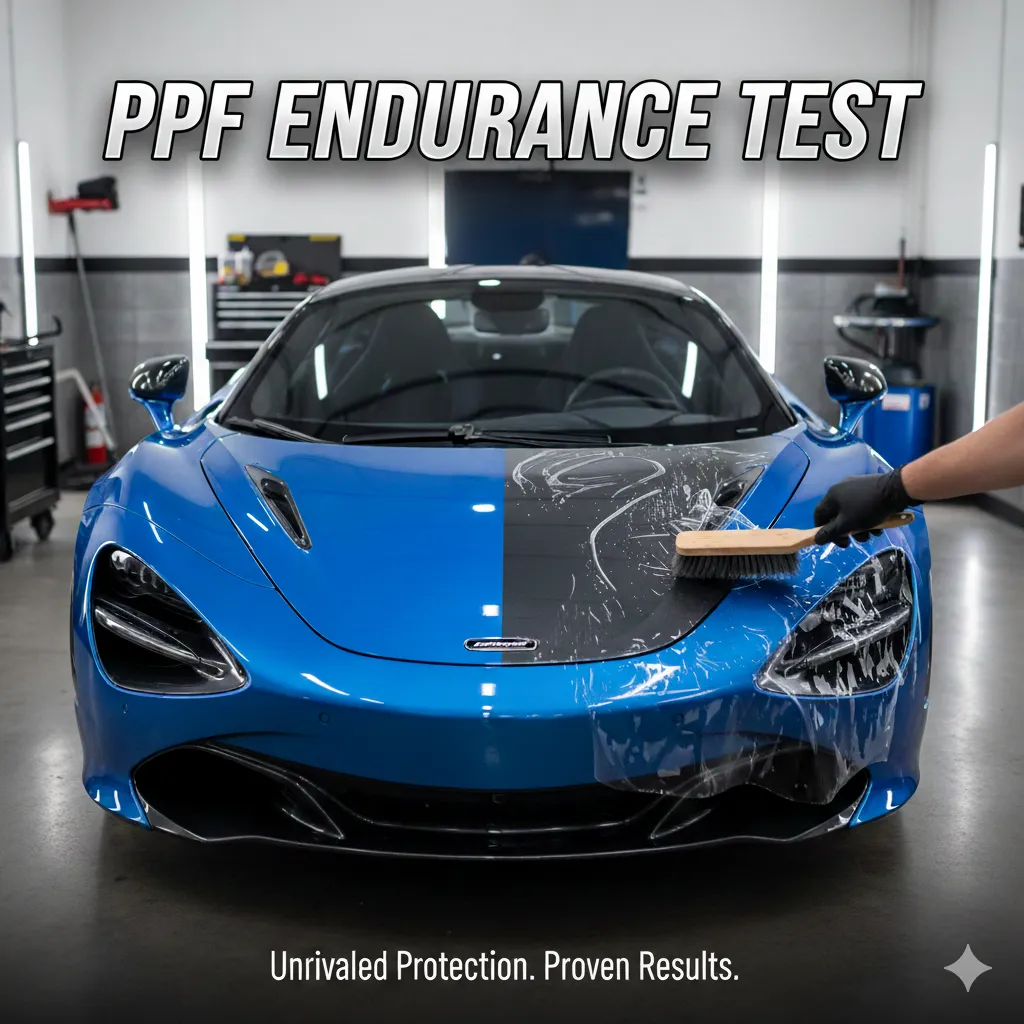

If you're a car enthusiast in Dubai, you know that your vehicle is more than just transportation it's an investment, a passion, and sometimes, a statement. With Dubai's intense sun, desert sand, and highway speeds, protecting your car's paint isn't optional; it's essential. That's where Paint Protection Film (PPF) comes in.

But here's the thing: not all PPF is created equal. The Dubai market is flooded with options, and unfortunately, some are far better than others. So how do you tell the difference between a film that'll truly protect your investment and one that's just clever marketing?

In this guide, we'll walk you through the science and practical methods of testing PPF quality—so you can make an informed decision before applying anything to your car.

What Makes a Quality Paint Protection Film?

Before we dive into testing methods, let's talk about what separates premium PPF from the rest. A high-quality paint protection film for your car should excel in several key areas:

Thickness and Durability: The film needs to be thick enough to absorb impacts from stones, sand, and road debris. Premium films use multi-layered Thermoplastic Polyurethane (TPU) construction.

Crystal-Clear Transparency: The best PPF is virtually invisible. It should maintain your paint's original gloss without yellowing over time, even under Dubai's harsh UV rays.

Self-Healing Properties: Top-tier films have a special top layer that heals light scratches and swirl marks when exposed to heat—pretty amazing when you see it in action.

Impact and Puncture Resistance: The film must be tough enough to take hits from flying stones without breaking down.

Now, let's get into how you can actually test these qualities.

Testing PPF Quality: The Professional Way

1. Does Film Thickness Really Matter?

Absolutely. Think of it this way: the thicker the film, the more material there is to absorb impact when a stone comes flying at your bonnet at 120 km/h on Sheikh Zayed Road. But it also needs to be flexible enough for proper installation around curves and edges.

The Tool: PPF Thickness Meter

This digital device gives you an instant, accurate reading of the film's thickness. A technician places the probe on the installed film (on a metal panel like your car's body), and boom—you get the measurement.

What to Look For: Quality paint protection film typically ranges between 8 mil (203 micrometers) and 12 mil (304 micrometers). If the meter shows significantly less than what the manufacturer claims, that's a red flag. You might be looking at a low-grade or even counterfeit product.

2. How Do You Test Puncture Resistance?

The whole point of PPF is to protect your paint from sharp objects and gravel. A film that punctures easily isn't doing its job.

The Tool: PPF Puncture Test Tool

This instrument simulates real-world scenarios where sharp, concentrated force hits the film. It grips a sample of the PPF and pushes a standardized probe (like a needle) into it with measured force.

What to Look For: The result is measured in Newtons or pounds of force required to pierce through the film. The higher the number, the better the puncture resistance. Premium films with quality TPU can withstand serious pressure without breaking down—unlike cheaper PVC-based alternatives that crack and fail.

This test is crucial in Dubai, where sand and small debris are constant threats on the roads.

3. What About Impact Resistance?

While puncture testing focuses on sharp objects, impact resistance is all about blunt force—like pebbles and stone chips hitting your car at highway speed. This is arguably the most important function of any PPF.

The Tool: PPF Impact Tester (Stone Chip Tester)

This specialized tool replicates the effect of road debris striking your vehicle. A sample is placed in the tester and subjected to controlled impacts.

What to Look For: With a quality film, you should see little to no damage—no cracking, chipping, or penetration. The TPU should flex and immediately bounce back, leaving the paint underneath completely protected.

Reputable manufacturers conduct extensive impact testing and publish their results, often referencing standards like ASTM (American Society for Testing and Materials). Ask to see this data before committing to a film.

4. Testing Flexibility and Stretch

High-quality PPF needs to be flexible and elastic for two critical reasons:

First, it allows proper installation around the complex curves and contours of modern vehicles without bubbles or lifting. Second, elasticity is what enables the self-healing properties that make premium PPF so desirable.

The Tool: PPF Stretching Instrument (Tensile Tester)

This machine measures how much the film can stretch before it breaks (elongation at break) and its tensile strength.

How It Works: A piece of PPF is clamped between two grips. One grip moves away from the other at a constant rate until the film tears. The machine records the percentage of elongation and the force required.

What to Look For: Premium TPU-based car protection film typically has an elongation rate exceeding 300% to 400%—meaning it can stretch several times its original length before breaking. This flexibility ensures durability and ease of installation.

Cheap PVC or low-quality TPU films snap at much lower stretch rates, making them difficult to install and prone to early cracking—especially in Dubai's heat.

5. How Do You Evaluate the Top Coat Quality?

Protection is vital, but aesthetics and maintenance matter too. A premium PPF should have a durable, high-performance top coat (often ceramic-infused) that provides excellent water resistance and protection against bird droppings, acidic rain, and road contaminants.

The Tool: PPF Water Sprinkler Display

While scientific labs use contact angle meters, many Dubai showrooms and detailing studios use this visual demonstration to show the film's hydrophobic properties.

How It Works: Water is sprayed onto a panel covered with paint protection film. The display lets you see how the water behaves—whether it beads up or spreads out.

What to Look For: On high-quality, ceramic-infused PPF, water should form tight, high-angle beads (ideally over 110 degrees). When more water is applied, it should roll off quickly, taking dirt and grime with it. This self-cleaning effect is what makes premium PPF so appealing.

Strong hydrophobicity means easier maintenance, better resistance to staining, and longer-lasting protection—essential in Dubai's dusty environment. If water spreads and sticks to the surface, the top coat is weak or non-existent.

Practical Tests You Can Do Yourself

While professional testing equipment gives definitive answers, there are some basic tests that you or an experienced detailer can perform to judge film quality.

Visual Clarity and Texture Test

How to Do It: Examine the film on a dark-colored panel under bright, direct light.

What to Look For:

Clarity: The film should be virtually invisible. Poor films often have a slight haze that dulls the paint's gloss.

Orange Peel: Check for orange peel texture—that dimpled surface that looks like, well, an orange. Premium films have a glass-smooth finish that enhances the paint's gloss.

The Self-Healing Test

How to Do It: Lightly scratch a small piece of PPF with your fingernail or a soft plastic tool to create surface scratches. Then, pour warm (not boiling) water over it, or use a heat gun on a low setting.

What to Look For: The scratches should visibly disappear as the heat causes the polymer molecules in the top layer to return to their original, smooth state. The speed and completeness of healing are key indicators of premium paint protection film.

This is especially impressive to witness and is a hallmark of quality TPU films.

Chemical Resistance Test

Important: This should only be done by professionals on a small, inconspicuous sample. Place a few drops of a common contaminant (like isopropyl alcohol or a mild solvent) on the film.

What to Look For: High-quality PPF should have a dense, solvent-resistant top coat that doesn't react. Poor films may immediately swell, haze, or lift when exposed to such chemicals.

What Happens If You Skip Quality Testing?

Choosing a film based solely on price or marketing claims—without asking about quality testing—can be risky. Here's what can go wrong with low-quality paint protection film in Dubai:

Yellowing: Cheap PVC-based films or low-grade TPU without proper UV inhibitors will yellow over time, especially on white or light-colored cars. This not only looks terrible but is expensive to remove.

Cracking and Peeling: Films that lack elasticity become brittle in Dubai's heat, leading to cracks at edges and seams. They'll start peeling prematurely, leaving your paint exposed.

Permanent Staining: A weak or absent top coat allows contaminants like bird droppings and bug splatter to etch into or stain the film permanently. Ironically, the film meant to protect your car can end up damaging it.

Adhesive Failure: Poor-quality adhesive can cause the film to lift or, worse, damage your car's clear coat when removed.

Why Professional Installation Matters in Dubai

Dubai's climate presents unique challenges. The extreme heat, constant sun exposure, and abrasive desert sand mean your PPF needs to be absolutely top-notch—and professionally installed.

At Superquick, we don't just apply film; we test it. We believe in radical transparency and expertise. Before we recommend any paint protection film for your car, we verify it meets our strict standards using the tools and methods outlined above.

We're not interested in selling you the cheapest option or the one with the flashiest marketing. We're interested in selling you the truth—a film that's been scientifically proven to perform.

Superquick's Commitment to Quality PPF

Our approach combines scientific testing with real-world Dubai conditions. We use:

PPF Thickness Meters to verify manufacturer claims

Puncture and Impact Testers to ensure road debris protection

Stretching Instruments to confirm flexibility and self-healing capability

Water Beading Demonstrations to show you the hydrophobic properties firsthand

Every film we install has passed rigorous testing. We're happy to show you the data, demonstrate the properties, and answer any questions about how your PPF will perform on Dubai roads.

Conclusion: Protect Your Investment the Right Way

Your car deserves protection that's scientifically proven—not just marketed. Now that you understand how to test PPF quality, you can make an informed decision. Look for films that are thick, durable, puncture-resistant, highly elastic, and hydrophobic. Choose a brand and installer who can provide proof of these qualities.

At Superquick, we're offering something special: free one-to-one personal assistance for all our customers and anyone interested in learning more about car care. Whether you need clarification on PPF options, want to understand different detailing services, or just have questions about choosing the right protection for your vehicle, we're here to help—at absolutely no cost.

Don't just protect your paint—fortify it with the best. Demand that your detailer can demonstrate film quality using proper testing methods. When you choose a professional who can back up their services with science, you're buying peace of mind knowing your car has the finest protection against Dubai's demanding conditions.

Ready to protect your investment?

📞 Call us: +971 52 315 1530

🌐 Visit: www.superquickdetailers.ae

Let's have a conversation about your car—no pressure, no sales pitch, just expert advice from people who genuinely care about automotive excellence.